Diesel Tanker Price: 13700 USD

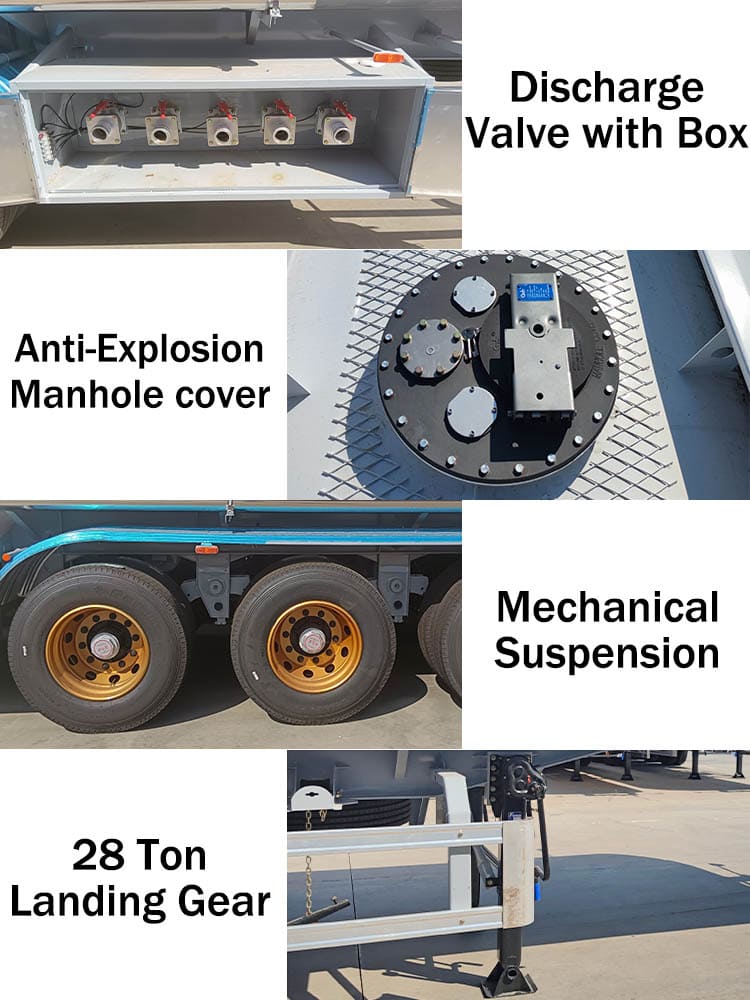

The diesel tanker capacity is a specialized transport vehicle designed for safely carrying various types of crude oil. The 40,000 liter diesel tanker model features a sealed tank structure to minimize leakage risks and meet the stringent safety requirements for transporting flammable and explosive substances.

TITAN offers flexible diesel fuel tanker dimensions to accommodate Sierra Leone customers, with optional tank capacities and a range of customization choices such as tank material, axle count, and layout configurations tailored to user-specific needs.

Specification of Diesel Fuel Tanker

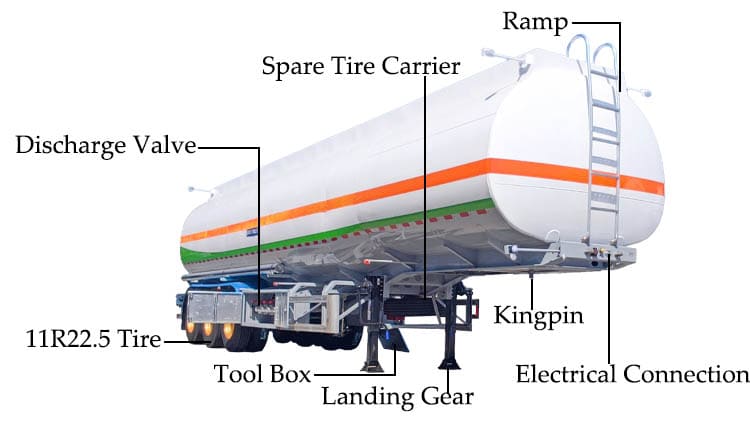

Dimension: 11000mm*2500mm*3800mm

Total volume(L): 40000L

Tanker Body Material: Q345 carbon steel

Manhole Cover: Carton steel

Axle: 3 axles TITAN brand, 13ton

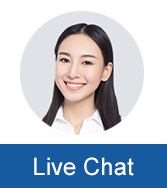

Landing Gear: FUWA brand, 28 ton

Suspension: mechanical suspension

Leaf Spring: 10 layers

Tire: 12 units, 11R22.5

Lamp: LED Lamp

Advantage of Diesel Tanker

To improve stability and protect the structure during transit, the diesel tanker capacity adopts a mechanical suspension system with multi-layered leaf springs. The design efficiently absorbs road-induced shocks, minimizing damage to the tanker frame and reducing internal fuel movement that could otherwise impact the tank walls.

Reinforcement is added to the suspension structure in all directions—front, rear, and sides—and includes a 70mm center balance pin. The robust setup helps mitigate the effects of frequent impacts from Sierra Leone rugged road surfaces and extends the diesel tanker overall service life.

For larger-capacity tanks, thickened anti-wave plates are installed inside the diesel fuel tanker to reduce the internal surge of fuel during braking or cornering.

The internal barriers safeguard the tank structure by evenly distributing the fuel's dynamic pressure. Additionally, TITAN allows clients to choose the location of the discharge valve—left or right side—based on operational requirements. Customized compartments can also be built into the tank, dividing into multiple sections to minimize fuel sloshing and enhance safety during Sierra Leone transport.

Following production, each diesel tanker capacity undergoes a series of rigorous inspections. Pressure tests are conducted to ensure that oil and gas vapors do not escape at elevated temperatures, maintaining safety both during operation and when parked.

A water injection test is used to verify the tightness of the tank seals, reducing the risk of fuel leakage. Furthermore, metal flaw detection technology is employed to assess the integrity of the tank's surface, helping confirm that the welds and structure are free from hidden defects.

Shipping of Diesel Tanker Capacity

To protect the diesel tanker during maritime shipment, TITAN implements a specialized packaging procedure. All 40,000-liter diesel fuel tanker are coated with protective wax to form a moisture-resistant layer. Waterproof tarpaulins are then applied to cover the entire diesel tanker. The two-step packaging solution provides strong resistance to corrosion caused by seawater and coastal humidity, ensuring the diesel fuel tanker arrives in top condition and ready for immediate use upon delivery.