Chapter 1: What is modular trailer?

Chapter 2: What is a SPMT trailer?

Chapter 3: What are modular trailer used for?

Chapter 4: What are the benefits of modular trailers?

Modular trailer in Sierra Leone are specialized vehicles designed to transport extra long, extra wide, extra high, and extra heavy cargo. Unlike conventional semi trailers, modular trailer utilize a modular design. The modular trailer consists of multiple axle units, each of which can be freely combined to accommodate cargo of varying weights and sizes. They are widely used for long and short distance transport of heavy equipment such as wind turbine equipment, transformers, bridge structures, and large machinery.

Features of Modular Trailer

The greatest advantages of modular trailer in Sierra Leone are their modular structure and high load capacity. Each axle unit typically consists of two, three, or four axles. By connecting multiple axle units longitudinally or transversely, they can form a massive transport platform with dozens or even hundreds of axles. Each axle can be independently steered and raised, and equipped with a hydraulic suspension system, they offer exceptional road adaptability and maneuverability.

Modular trailer in Sierra Leone offer strong load capacity and evenly distributed loads, preventing concentrated forces from damaging cargo or roads. Equipped with a variety of steering methods, including mechanical, hydraulic, or electronically controlled, they enable flexible maneuvers on narrow roads or in complex terrain, ensuring safe transportation.

Classification of Modular Trailer

Based on their power systems and control methods, modular trailer in Sierra Leone can be broadly divided into the following three types:

Mechanical Steering Modular Trailer

This type of modular trailer relies on a front tractor for power, utilizing a mechanical linkage system to achieve simultaneous steering of multiple axles. Its simple structure makes it suitable for short distance, medium to low speed transport or transportation on roads with good conditions.

Hydraulic Steering Modular Trailer

Equipped with an advanced hydraulic steering system and lift suspension system, hydraulic steering modular trailer in Sierra Leone can independently adjust the height and steering angle of each axle. Compared to mechanical steering, hydraulic steering offers greater flexibility and is suitable for transporting larger loads and complex roads. It is currently the most widely used type in the construction industry.

Self Propelled Modular Transporter (SPMT)

SPMT trailer in Sierra Leone is a high end, heavy load transport vehicle that requires no tractor and is self-powered and remotely controlled. Its most notable feature is its 360 degree on-the-spot steering, exceptional maneuverability, and high load capacity. SPMT trailer is widely used in industries with demanding transport requirements, such as shipbuilding, offshore platforms, nuclear power plants, and aerospace engineering. SPMT trailer utilizes a hydraulic system to control all operations, which can be controlled remotely or from the cockpit.

Modular trailer in Sierra Leone, as essential equipment in the specialized transport sector, play an irreplaceable role in oversized and unrestricted transport. Whether traditional mechanical modular transporters, flexible and efficient hydraulically steered transporters, or intelligent and advanced SPMT systems, each offers its own advantages, adapting to diverse transport needs.

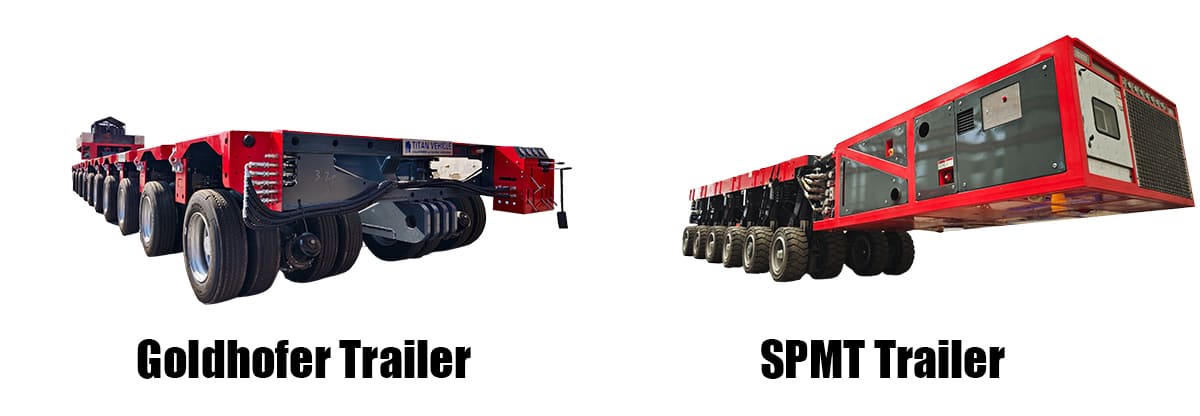

Goldhofer Trailer | SPMT Trailer | Modular Trailer in Sierra Leone

SPMT trailer in Sierra Leone is an ultra large, flexibly modular specialized transport vehicle primarily designed for the precise handling of overweight and oversized cargo. SPMT trailer is widely used in the petrochemical, heavy machinery manufacturing, bridge construction, nuclear power engineering, and other fields. Unlike traditional semi trailers, the SPMT does not rely on a tractor for towing. Equipped with its own power system and control system, SPMT trailer in Sierra Leone enables independent driving, steering, and precise positioning, making it a super sized piece of equipment for heavy duty logistics.

Overall Features: A Perfect Combination of Modularity and Flexibility

The core advantage of the SPMT trailer in Sierra Leone lies in its modular design. SPMT trailer consists of multiple independent modules, each typically including a power system, hydraulic drive unit, tire assembly, and control system. These modules can be combined through mechanical connections and electronic synchronization systems to form transport platforms of varying lengths and widths. For example, depending on the weight and size of the cargo, two, four, or even dozens of modules can be combined to form an extra long flatbed, with a maximum load capacity of tens of thousands of tons. This makes it easy to handle oversized cargo such as giant pressure vessels, bridge box girders, and nuclear reactors.

The modular design of the SPMT trailer in Sierra Leone not only accommodates diverse cargo sizes but also evenly distributes weight by adjusting the number and distribution of tires, avoiding excessive ground pressure. Even on ordinary roads or temporary sites, the increased tire contact area reduces ground pressure, meeting transportation needs in complex environments.

Key Structures and Functions: A Precision Controlled Mobile Platform

1. Power and Drive System

Each SPMT trailer in Sierra Leone is equipped with an independent diesel engine or electric motor, which drives the travel motors via a hydraulic pump, achieving synchronized rotation of the tires. SPMT trailer power system supports multi-module coordination, ensuring consistent speed and torque across all units, preventing cargo shifting or equipment damage due to uneven power.

2. Steering and Positioning System

SPMT trailer's tires enable 360 degree steering, including various modes such as straight, diagonal, sideways, and pivoting. Its minimum turning radius is virtually zero, enabling flexible maneuvering in confined spaces. Its control system uses laser ranging, GPS positioning, or wireless remote control technology to achieve millimeter level precision in mobile positioning, ensuring precise alignment of cargo during installation or docking. For example, during nuclear power plant construction, reactor pressure vessels weighing tens of tons can be lifted into place with pinpoint accuracy.

3. Load bearing and Shock-absorbing Structure

SPMT trailer's load bearing platform is welded from high strength alloy steel, boasting a smooth, non-slip surface. Loads can be secured with bolts or specialized clamps. A hydraulic suspension system beneath the platform automatically adjusts its height based on road undulations, reducing vibration during transport and protecting delicate equipment or fragile components (such as large glass curtain walls and precision machine tools). Furthermore, the suspension system can be raised and lowered as a whole, facilitating loading and unloading of cargo and docking with other equipment.

4. Control System

SPMT trailer in Sierra Leone utilizes a centralized intelligent control terminal. Operators can synchronize multiple modules using a console or wireless remote control, monitoring parameters such as power output, pressure, and temperature of each unit in real time. Some high end SPMT trailer also feature automatic path planning and, combined with sensors, obstacle avoidance, further enhancing operational safety.

Application Scenarios: Challenging the Impossible in Heavy Duty Transport

The emergence of SPMT trailer in Sierra Leone solves the challenges of handling oversized cargo that traditional transport vehicles struggle to address. In the petrochemical industry, SPMT trailer can transport cracking furnaces and reactors weighing hundreds of tons. In bridge construction, SPMT trailer can transport prefabricated box girders directly from the production base to the erection site. In the aerospace industry, SPMT trailer can carry rocket boosters or satellite launchers for short distance transport. Furthermore, in post-disaster relief, SPMT trailer in Sierra Leone can be used to move heavy rescue equipment or clear large debris.

Compared to traditional trailers, SPMT trailer do not require large tractors and can dynamically adjust their load capacity through modular assembly, significantly reducing transport route and site requirements. The SPMT trailer's precise maneuverability and stability make it an indispensable core piece of equipment in modern heavy duty logistics, facilitating the efficient implementation of ultra-large projects.

In short, SPMT trailer in Sierra Leone, with its modular design, omnidirectional mobility, and ultra high load bearing capacity, has redefined heavy duty cargo transportation and set a new standard for precise, efficient, and safe transportation in the industrial sector.

Goldhofer Trailer | SPMT Trailer | Modular Trailer in Sierra Leone

Applications of Goldhofer Trailer

Goldhofer trailer in Sierra Leone, renowned for their exceptional performance and reliability, play a critical role in numerous industries.

In large scale construction projects, such as bridge construction, Goldhofer trailer in Sierra Leone shoulder the heavy responsibility of transporting massive bridge components. For example, prefabricated box girders, tens of meters long and weighing hundreds of tons, are precisely transported from the prefabrication yard to the construction site. The Goldhofer trailer's multi-axle design evenly distributes the load, reducing road pressure and adapting to various road conditions for safe transportation. In complex mountainous areas or narrow streets, Goldhofer trailers, with their flexible steering system, including wide angle steering, enable precise maneuvering, allowing them to navigate curves and narrow sections, ensuring timely delivery of construction materials.

In the energy sector, the booming wind power generation sector presents unique transportation challenges. Goldhofer trailer in Sierra Leone are highly capable of transporting extremely long and large wind turbine blades and towers. For example, when transporting blades, Goldhofer trailers can be equipped with a specialized telescopic mechanism that adjusts to blade length, accommodating blades 70 meters or longer. When transporting towers, the Goldhofer trailer's robust load bearing capacity ensures tower stability during long distance transport, preventing damage from bumps and jolts, thus providing a solid transportation guarantee for the efficient development of the wind power industry.

The heavy machinery manufacturing industry also relies on Goldhofer trailer in Sierra Leone. When transporting large machine tools, mining machinery, and other equipment, these devices are often enormous and heavy. With their strategically located axle layout and high strength frame structure, Goldhofer trailers can carry hundreds of tons of equipment, safely transporting completed heavy machinery to various locations, facilitating product distribution and application within the manufacturing industry.

Applications of SPMT trailer

SPMT trailer in Sierra Leone, with its high flexibility and robust load bearing capacity, demonstrates unique value across multiple industries.

In the petrochemical industry, SPMT trailer in Sierra Leone are commonly used to transport large refining equipment and oil storage tanks. These equipment are not only extremely heavy but also require extremely high stability and precise positioning during transportation. The modular design of the SPMT trailer allows for flexible configuration based on the size and weight of the equipment. By working together, multiple modules can achieve loads of tens of thousands of tons. Furthermore, the SPMT trailer's advanced hydraulic suspension system automatically adjusts its height to adapt to varying road conditions, reducing vibration during transportation and ensuring the integrity of the equipment, thereby ensuring the smooth construction and operation of petrochemical projects.

In the shipbuilding industry, SPMT trailer is used to transport hull sections and large marine engines. Space in shipbuilding workshops is limited, and the SPMT trailer's omnidirectional steering allows for flexible maneuvering within confined spaces, precisely transporting large hull components to their assembly locations. For example, when installing a marine engine onto a ship, SPMT trailer can precisely control its position and angle, ensuring perfect alignment between the engine and the hull, improving the efficiency and precision of shipbuilding.

Nuclear power engineering is one of the fields with the most stringent requirements for transportation safety and precision, and the SPMT trailer in Sierra Leone plays an irreplaceable role in this area. When transporting critical equipment such as nuclear reactor pressure vessels, the SPMT, with its precise positioning system and stable driving performance, ensures absolute safety during transportation. Operators can remotely control the SPMT trailer to achieve millimeter-level movement accuracy, meeting the extremely high requirements of nuclear power equipment installation and ensuring the smooth progress of nuclear power project construction.

In large scale bridge replacement projects within infrastructure construction, the SPMT trailer in Sierra Leone can be used to remove old bridge structures and transport new bridge components. It can transport and install large bridge structures without damaging surrounding roads and infrastructure, minimizing impact on traffic and the surrounding environment, and efficiently promoting the implementation of bridge construction and replacement projects.

Goldhofer Trailer | SPMT Trailer | Modular Trailer in Sierra Leone

Modular trailer in Sierra Leone, core equipment in the oversized and unrestricted transport industry, are widely used for transporting heavy cargo such as wind turbine equipment, bridge components, petrochemical plants, ship structures, and large scale construction machinery, thanks to their strong load bearing capacity, flexible assembly structure, and excellent adaptability. Goldhofer trailer and SPMT trailer represent two of the industry's leading transport solutions, each with unique advantages that meet diverse project scenarios and customer needs.

Advantages of the Goldhofer Trailer

Goldhofer trailer in Sierra Leone are widely used worldwide thanks to their superior design and manufacturing process. Their advantages are reflected in the following aspects:

Modular Assembly, Free Combination

Goldhofer trailer in Sierra Leone feature a fully modular design, allowing users to flexibly combine the number and configuration of axles based on the size and weight of the cargo. By combining them longitudinally, transversely, and even stacking them vertically, they can create transport configurations of any load capacity, offering exceptional adaptability.

Strong Load Bearing Capacity and Stability

Each axle of the Goldhofer trailer in Sierra Leone boasts an exceptional load bearing capacity, with a single axle capable of carrying up to tens of tons. The entire vehicle frame is constructed of high strength steel, offering a sturdy structure and excellent bending and torsional resistance, ensuring excellent stability even when transporting heavy loads.

Hydraulic Suspension and Steering System

Goldhofer trailer in Sierra Leone are equipped with an advanced hydraulic suspension system. Each axle can be raised and lowered independently, ensuring the cargo remains level on uneven surfaces and improving vehicle maneuverability. Furthermore, the Goldhofer trailer's hydraulic steering technology enables flexible, wide-angle turns and smooth maneuverability even in narrow sections.

High Adaptability and Compatibility with Various Power Units

Goldhofer trailer in Sierra Leone can be used with various tractor brands and can even be combined with modular trailers from other brands. This robust system compatibility provides customers with greater operational flexibility.

High Transport Efficiency and Excellent Cost Effectiveness

Compared to fully automated systems, Goldhofer trailers offer lower investment costs and simplified maintenance, making them suitable for high frequency, medium and long distance heavy duty transport missions. Goldhofer trailer in Sierra Leone are ideal for time sensitive applications such as wind power, engineering projects, and bridge construction.

Goldhofer Trailer | SPMT Trailer | Modular Trailer in Sierra Leone

Advantages of the SPMT trailer

SPMT trailer in Sierra Leone is a self propelled modular transport system that does not rely on a tractor and utilizes an electro hydraulic system for all movements. SPMT trailer is commonly used for transporting extremely heavy, complex, or indestructible large equipment. Its advantages are primarily reflected in the following aspects:

Self Powered and Independent Operation

SPMT trailer in Sierra Leone features a built in diesel power pack or electric drive system, allowing it to operate independently without an external tractor. This independent operation makes it extremely efficient for transporting equipment in enclosed areas such as large factories, ports, nuclear power plants, and shipyards.

360 Degree Steering for Superior Maneuverability

SPMT trailer in Sierra Leone supports all-round, multi axle independent electronic steering, enabling on-the-spot rotation, lateral movement, and diagonal movement. It easily handles confined spaces, complex routes, and requires high precision positioning, making it an irreplaceable solution for transporting oversized items.

Highly Precise Control System

SPMT trailer in Sierra Leone, through remote control or a pilot control system, allows the operator to precisely control the direction, speed, and height of each set of wheels, achieving millimeter level maneuverability. This makes it suitable for demanding applications such as alignment and overall lifting.

Multi vehicle linkage for seamless coordination

SPMT trailer in Sierra Leone supports multi-module and multi-axle linkage, enabling up to hundreds of axles to be combined, capable of transporting thousands or even tens of thousands of tons of cargo. The highly intelligent linkage system ensures synchronized and stable operation of multiple vehicles.

Adaptable to Extreme Loads and Structures

SPMT trailer in Sierra Leone can carry extreme loads with irregular centers of gravity, such as offshore platforms, rocket launch towers, and nuclear reactors. It is the preferred solution for missions where traditional axle-lift vehicles struggle.

Advanced Technology and High Level of Automation

Most SPMT systems feature automatic load distribution, route planning, remote monitoring, and diagnostics, making them suitable for high standard, high risk, and high precision engineering transport projects.

Goldhofer trailer with their cost effectiveness, flexible assembly, and exceptional load capacity, are widely used in global engineering construction, wind power, mining, and bridge transport projects. SPMT trailer, on the other hand, demonstrates unparalleled intelligent control and powerful load bearing capabilities under extreme conditions, making it particularly suitable for the integrated transport of large industrial structures. Both systems, with their respective strengths, together form the core technical strength of modular transport solutions, providing solid support for major projects worldwide.

Goldhofer Trailer | SPMT Trailer | Modular Trailer in Sierra Leone