Container Handling Forklift Price

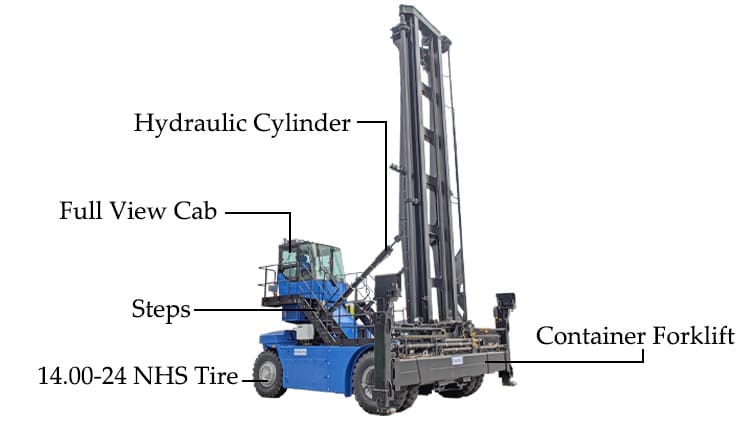

The XCMG container handling forklift is designed specifically for lifting, stacking, and transporting empty containers, making it a valuable asset in ports, container yards, and logistics facilities throughout Sierra Leone. With its strong build and efficient handling, it plays a vital role in supporting daily operations where speed and reliability are crucial.

Spec of Container Handling Forklift

Engine Model: VOLVO TAD851VE

Rated power/speed: 185/2200kW/rpm

Maximum torque/speed: 1160/1350Nm/rpm

Exhaust emission standards: 3 stages

Gearbox model: DANA 13.7HR32334

Drive axle model: Kessler D81PL488

Spreader Model: XDJ90

Side shift distance: 600mm

Self-respect: 4.7t

Suitable: ISO 20/40 ft container

Tires: 14.00-24-28PR

Advantage of Container Handling Forklift

At the top of the mast sits the spreader, the main component that grips and secures containers during movement and stacking. Most empty container handling for sale are equipped with hydraulic twist-lock mechanisms along with side clamps, giving them the flexibility to manage both 20-foot and 40-foot empty containers with ease.

The chassis is built with durability and balance in mind. Using heavy-duty steel and a low center of gravity, the structure ensures that the machine remains steady when dealing with demanding lifting tasks. This stable base is essential in the busy container environments of Sierra Leone, where container handling forklift must perform reliably under continuous workloads.

At the core of the empty container handling's performance is the hydraulic system, which powers the lifting and gripping functions. Precision-engineered pumps and valves allow quick yet controlled movement of both the mast and the spreader. Many modern models integrate communication systems or programmable controllers, which synchronize multiple operations, strengthen safety interlocks, and even allow for remote monitoring.

Mobility is another crucial aspect of empty container handling design. Large pneumatic or solid tires are commonly used to provide stability and absorb shocks, especially on rough or uneven yard surfaces. Advanced steering systems, including rear-axle or multi-directional steering, allow sharp turns and smooth maneuvering in confined spaces. This is particularly valuable in the container terminals of Sierra Leone, where storage areas are often crowded and require precise navigation.

Safety features are built into every stage of operation. Load sensors prevent over-lifting, while speed limiters, anti-rollover systems, and overload warnings further reduce risks. Together, these technologies create a safer working environment for both operators and equipment, ensuring that empty container handling in Sierra Leone can be carried out efficiently without compromising safety.