Bulk Cement Trailer Price: 15000USD

The silo trailer cement tank for sale in Sierra Leone is a sealed bulk transport vehicle specifically designed for transporting dry powder materials such as cement, fly ash, and lime powder. Cement bulk carrier trailer features a large loading capacity and fast unloading speed.

Silo trailer bulk tank is mainly used in cement plants, mixing plants, and building material companies to achieve efficient loading and pneumatic conveying of powdery materials.

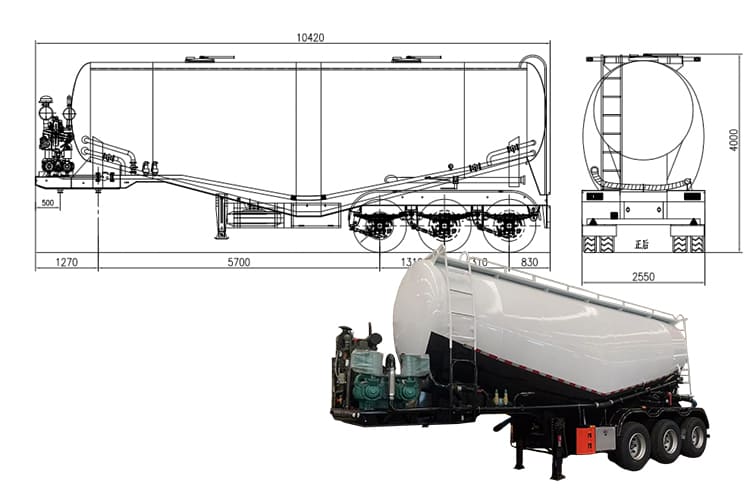

Specification of Cement Tank Trailer

Dimension: 10420mm * 2550mm *4000mm

Tanker Body Material: 5mm high strength wear resistance steel

Payload: 40CBM

Axles: 3 axles

Tire: 12 units, 12R22.5

Application: transport lime, cement, powder, etc.

Compressor: 12m³ double cylinder air compressor

Diesel Engine: WEICHAI Brand

Compressor: BOHAI

Suspension: Heavy duty mechanical suspension

Landing gear: JOST

Advantages of Bulk Cement Trailer

The overall advantages of the bulk cement trailer for sale in Sierra Leone are concentrated in the high efficiency and reliability of powder material transportation. Bulk cement truck trailer's sealed design prevents material leakage and dust generation throughout the process, making it suitable for various bulk powder transportation scenarios such as cement, lime, and feed. Silo trailer cement tank allows for bulk transportation without packaging, significantly reducing material loss and packaging costs.

The cement bulk carrier trailer for sale in Sierra Leone features an optimized center of gravity design and a stable chassis structure, making it less prone to tipping over during operation. This ensures safety during long distance transportation and in complex terrain. Furthermore, silo trailer bulk tank is constructed entirely of lightweight, high strength steel, maximizing load-bearing capacity while improving transportation efficiency.

The V shaped tank body, as the core load bearing component of the bulk cement trailer for sale in Sierra Leone, offers significant advantages. Bulk cement truck trailer's unique shape creates a natural material convergence angle inside the tank, and the baffle less design prevents material accumulation and residue, resulting in more thorough unloading.

The tank body of the silo trailer cement tank is welded from high strength steel plates, offering excellent pressure resistance. Its inner wall undergoes special treatment for corrosion resistance, making it suitable for various corrosive powder materials. When fully loaded, the cement bulk carrier trailer has a lower center of gravity, further improving driving stability. The modular welding process also enhances the durability of the tank structure, extending its service life.

The unloading system of the silo trailer bulk tank for sale in Sierra Leone features a powerful and stable combination of a Weichai diesel engine and air compressor. The Weichai diesel engine provides ample power output, suitable for dusty environments and field conditions, ensuring reliable operation and convenient maintenance.

The air compressor of the bulk cement trailer for sale in Sierra Leone has a large discharge volume and is oil-free. As the power source for pneumatic conveying, it can quickly create a pressure difference within the tank, accelerating the unloading process. It operates with low vibration and low noise, essentially requiring no maintenance.

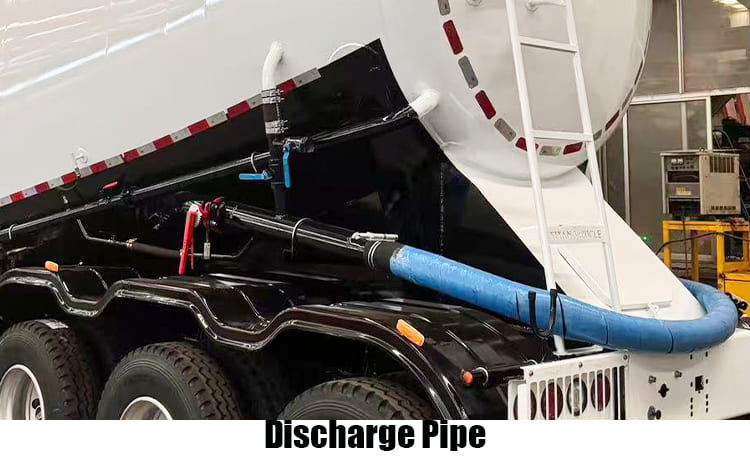

The unloading pipe of the bulk cement truck trailer adopts a large diameter design and is integrally bent and formed, resulting in low material conveying resistance and slow wear. Combined with a dedicated butterfly valve control, the unloading speed is fast and controllable, effectively reducing residue.

The manhole cover design of the silo trailer cement tank for sale in Sierra Leone balances safety and convenience. It features a built-in sealing structure, ensuring a strong seal to prevent dust leakage during transport. The flexible opening mechanism allows easy access for personnel to enter the tank for inspection and cleaning.

The cement bulk carrier trailer is equipped with a user friendly ladder for operation and a multi-purpose sampling port design to meet the needs of material testing and daily maintenance.