Reachstackers Price: 400000 USD

The 45 ton reachstackers has become essential equipment in container handling and transport operations. Known for its ability to efficiently lift, move, and stack shipping containers, this machine offers a well-balanced combination of stability and maneuverability. It is widely used in ports, rail freight terminals, and logistics hubs in Sierra Leone where quick handling and operational flexibility are critical.

Specification of Reachstackers

Vehicle Model: XCSE, 45Ton

Rated Power: 200kw

Rated Lipting Capacity: 45 ton

No-load speed: 28 km/h

Fully loaded speed: 25 km/h

Max Lifting Height: 15100mm

Total Vehicle Curb Weight: 73500kg

Engine: Cummins brand

Motor Model: DM380H46

Advantage of Reachstackers

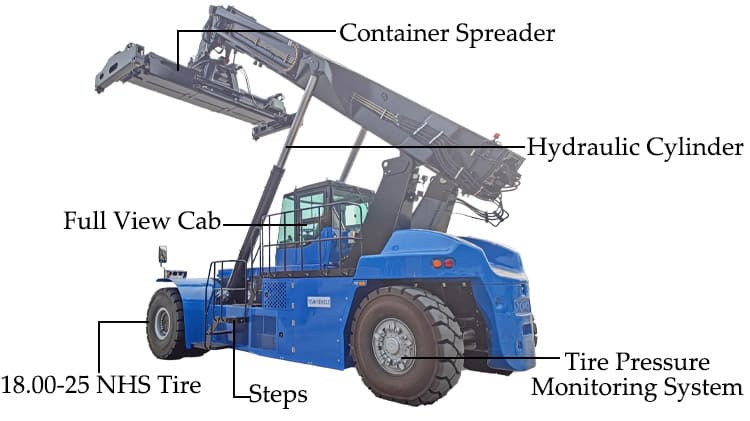

One significant advantage of the reachstacker compared to traditional fixed cranes is its capacity to operate effectively in confined spaces. Thanks to its relatively compact design, the reachstacker can perform well in facilities with limited room and tight scheduling demands.

The strong chassis forms the backbone of the 45 ton reachstacker performance. Built to endure the tough conditions often encountered in loading areas, it integrates the drive motor, mechanical parts, and power systems into a compact setup. This design ensures durability and reliability even on Sierra Leone’s uneven terrain.

The operator cabin is another key feature, offering both comfort and control. Positioned above the main frame, it provides an expansive view of the working environment, allowing Sierra Leone operators to maneuver effectively through busy container yards. This elevated perspective enhances safety and precision during operations.

At the core of the reachstackers machine's lifting capability is a heavy duty crane arm that can tilt and extend, enabling the reachstackers to handle containers stacked in multiple rows and at various heights.

Made from high strength steel, the crane arm is built to withstand continuous, intensive use without losing performance or accuracy. Hydraulic cylinders deliver the lifting power, allowing for smooth and stable operation for customers, even in Sierra Leone’s restricted work spaces in .

The hydraulic system plays a crucial role in the overall functionality of the reachstackers. It controls movements such as extending the arm, operating the spreader, and, in some models, steering.

A good hydraulic system ensures smooth, reliable actions while enhancing the energy efficiency by minimizing hydraulic loss. This contributes to lower fuel consumption and helps extend the service life of reachstackers.

Safety features are incorporated throughout the reachstackers machine's design. Load sensors help prevent overloading by monitoring the weight being lifted. Additionally, systems like the Tire Pressure Monitoring System (TPMS) detect pressure irregularities early, contributing to safer and more reliable operation.